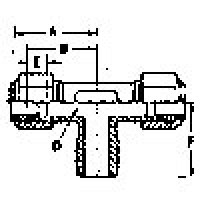

Brass Male Brnch Tee 272P03X02

MFR Model# 272P-03X02

- JUMP TO

- Overview

- Accessories

- Reviews

- Q&A

- View in Catalog

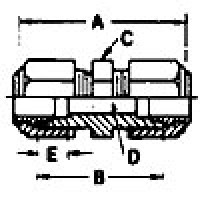

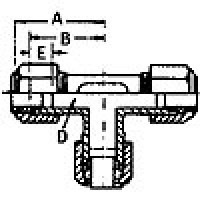

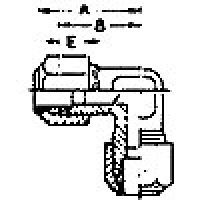

| Type | Tube O.D. | Thread Size | Part No. |

|---|---|---|---|

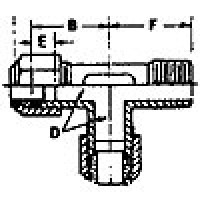

| 272P - Male Branch Tee | 3/16 | 1/8 | 272P-03X02 |

Overview

|

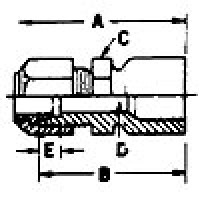

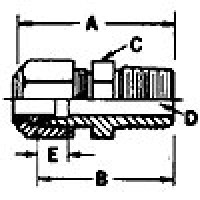

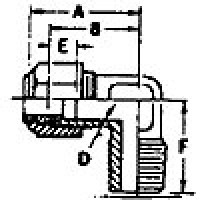

Poly-Flo Flareless tube fittings consist of a brass body and nut with brass sleeve. Use with PolyFlo, PVC or Nylaflow pressure tubing. The Poly-Flo fittings have the same configuration as Nylo-Seal fittings of the same basic part number. Note: The fittings are sold individually and not in pair. Brass Poly Flo fittings cannot be used with NSR tubing listed. Use SAE fittings, see Accessories tab. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

FAST SERVICE, JUST WHAT I NEEDED.

These brass fittings are smaller than the plastic ones, and clamp onto the tubing much better. Made the pitostatic install very nice.

Have used these for years and they work well

Hard to find this item anywhere - Aircraft Spruce had them! I had some trouble with sign in and online order, but phone conversation made the order work.

I mostly ordered the brass fittings however i did also order one of the nominal 1/4 NYLO-SEAL poly tees, (ACS 264-N04) and 10 ft of nominal 1/4 Poly-Flo tubing, (ACS 44-P) . My aircraft static and pitot system is a mixture of the brass and poly fittings but my intent over time, is to replace the poly fittings with brass. There is nothing wrong with the poly fittings however the brass ones are generally smaller and have an internal tubing reinforcement that fits the ID of the nominal 1/4OD poly tubing, hence the little plastic insert that one would need with the poly fittings is not required. To me, the brass makes a neater install and fits better in cramped panel locations. In my case, I had to install two male run tees to the rear of my airspeed. The spacing of the static and pitot inlets was too tight to allow the screwing in of two poly male run tees however the brass were just small enough that the two fit. side by side, even with the internal tubing ID reinforcement pipe sticking out of the middle opening. I was disappointed that ACS does not stock the brass male run tee with the nominal 1/8 NPT threaded end that screws into the rear of many nominal 3 round instruments. While I was able to obtain elsewhere a brass 1/8 NPT Parker 171P-4-2 (aka Dayco 271P04x02) male run tee, the 1/4 NPT male run tee (ACS 271P-04) they do stock was not quite what I needed. Other than that one fitting, the ACS selection is quite adequate.

Exactly what I need

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

These can be re-used but they should be inspected before doing so. If there is damage to the fitting it should be replaced. It is at the discretion of the installer whether it should be replaced or not. We cannot, as a blanket statement, say they can all be reused.

You insert the tube into the nut and then tighten the nut on to the fitting. The vendor tightening spec is "finger tight, plus a 1/4 turn with a wrench."

That would be the 268 model. Those have nylon inserts on the nuts on them.

Up to 1200 psi.

No, sealant is not necessary.

Yes, the brass Poly-flo fittings are required for Use with PolyFlo, PVC or Nylaflow pressure tubing

FREE Shipping

FREE Shipping