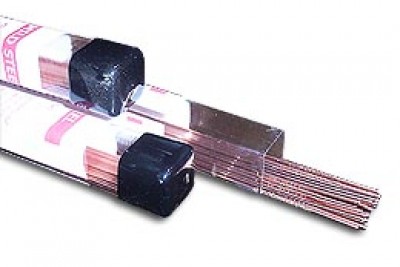

Nickle 625 .035 Tig Filler Material

MFR Model# NICKEL625-.035

Overview

|

Washington Alloy 625 is a nickel-chromium-molybdenum filler metal used for MIG, TIG, submerged arc and plasma arc welding on Inconel alloys 601, 625 and 690 as well as Incoloy alloys 800, 825 and 800HT to themselves or to each other. Washington Alloy 625 is excellent for joining these Inconel and Incoloy alloys to dissimilar metal such as carbon steel, low alloy steel, ferritic and austenitic stainless steels. This filler metal produces weld deposits with excellent corrosion and oxidation resistance against phosphoric acids, organic acids and seawater. Good resistance against pitting and stress corrosion cracking in chloride containing environments. The weld deposits exhibit high strength and fatigue resistance over a broad range of temperatures ranging from cryogenic up to 1800°F. Applications: Washington Alloy 625 is most commonly used in the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts. Also used in the aerospace industry for thrust reverser assemblies, fuel nozzles, after-burners and combustion systems. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- Produces weld deposits with excellent corrosion and oxidation.

- Resistance against phosphoric acids, organic acids and seawater.

- Good resistance against pitting and stress corrosion cracking in chloride containing environments.

- Commonly used in the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts. Also used in the aerospace industry for thrust reverser assemblies, fuel nozzles, after-burners and combustion systems.

Specifications

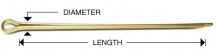

- .035" thick.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping