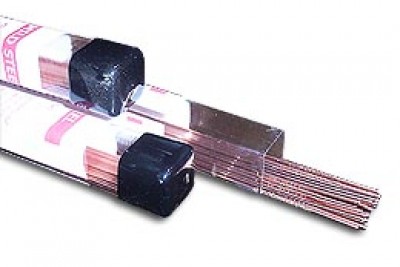

Mild Steel Alloy Er80S-D2 1/16Tig Filler Material

MFR Model# ER80SD2-063-10T

Overview

|

Sold by the lb USA 80S-D2 is designed to give high strength weld son high sulfur bearing (free-machining) steels or medium carbon steels. This wire contains additional amounts of manganese and silicon which, when alloyed with 0.50% molybdenum, produces weld deposits which have high ductility, excellent impact values and tensile strengths of approximately 100,000 psi. USA 80S-D2 is commonly used on low carbon and low alloy steels such as AISI 4130 where tensile strengths provided by plain carbon steel wires are inadequate. A well balanced silicon content gives this wire superior arc stability, a low spatter level and a flat bead with excellent appearance. USA 80S-D2 produces X-ray quality, porosity free welds even over dirt, rust or mill scale. Applications: |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- Well balanced silicon content gives this wire superior arc stability, a low spatter level and a flat bead with excellent appearance.

- Produces X-ray quality, porosity free welds even over dirt, rust or mill scale.

- This wire is commonly used on low carbon and low alloy steels.

Specifications

- 1/16" x 36"

- Elongation is 25%.

- Tensile strength: approximately 100,000 psi

Reviews

Good

High quality rods, makes very strong TIG welds, can also be used for gas welding.

As addvertised

I hate to admit it but I bought this to use for pattern making of tubing projects. Its nice and straight and bends easily of course. As far as tig welding I have no idea how well it works.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping