Lycoming Valve Spring Compressor

MFR Model# TP687

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

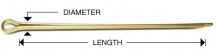

| This cast aluminum alloy valve spring compressor fits Lycoming parallel valve and angle valve horizontally opposed engines. An excellent tool at an economical price. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Frequently Purchased With

Customers Also Viewed

Reviews

I used the tool to check out my number one cylinders exhaust valve. The tool is aluminum alloy and is light weight but seems strong enough for the job. There was no bending of the tool in use. It works fine. Expensive for what it is.

Valve Spring Compressor For Lycoming Engines

Worked great on my parallel valve Lycoming.

Valve Spring Compressor For Lycoming Engines

Excellent Tool, worked exactly as required. Good quality.

Valve Spring Compressor For Lycoming Engines

Worked Very Well. Upon Assembly, Compressed Valve Spring & easily installed Keepers.

Valve Spring Compressor For Lycoming Engines

very good tool, to prevent damage , schock off tapets before using tool.

Valve Spring Compressor For Lycoming Engines

Good product, fast shipping!!

Valve Spring Compressor For Lycoming Engines

The price everybody charges for this simple tool is beyond stupid high. They know you need it, and they make you pay to get it. No scruples, no shame. Nearly a hundred dollar bill for a bent piece of aluminum. And this is the cheap version. Sheesh!

Valve Spring Compressor For Lycoming Engines

Works well.

This tool lasted for eight years with all kinds of student abuse at our A and P school. It took only one student not paying attention to break it. If it were made of steel a student could break it.

Aluminum... Its more expensive and weaker than steel??? Wonder who was the genius behind that!!!!

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping