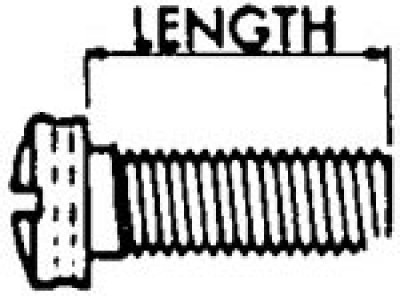

MS35265-80 Fillister Head Screw

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

| Part Number | Type | MS Dash # | Length (in.) | Thread Size | Buy Undrilled |

|---|---|---|---|---|---|

| AN500-A416-10 | Coarse Thread | MS35265-80 | 5/8 | 1/4-20 | -- |

Overview

|

All part numbers will follow this format: AN###. To further distinguish between the part numbers, you'll notice that a dash ("-") has been added, followed by some specific variation of more numbers. If there is an "A" after the dash, the part is cadmium plated, Type II, Class 3, with a drilled head. If there is NOT an "A" after the dash, the part is Cadmium plated, Type I. AN500 (coarse thread) and AN501 (fine thread) slotted fillister head screws are fabricated from carbon steel. Tensile strength 55,000 PSI AN502 (fine thread) and AN503 (coarse thread) drilled head, slotted fillister head screws are fabricated from steel meeting specification MIL-S-6050. Tensile strength 125,000 PSI. Cadmium plated, Type II Class 3. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Replaces the Cessna Baffle Screws much better than using the Lycoming valve cover screws with their captive lockers.

MS35265-80 Fillister Head Screw

fine

MS35265-80 Fillister Head Screw

Perfect fit for continental valve covers when installing REAL rubber gaskets.

MS35265-80 Fillister Head Screw

Work great for replacement valve cover screws on Continentals with REAL Gaskets.

MS35265-80 Fillister Head Screw

Just as advertised.

My first order was to see if these were correct length(no grind down to fit) for SU Carburetors Suction Chamber screws,This is my 2nd order of these Fillister Head screws as they are better than stock head diameter and of course Safety Wire Drilled !! Wont use anything else on my Carb Rebuilds !!

1st order to make sure they were correct for my carb rebuilds !! And they are perfect for 60s era SU Carb resto race look !! Thanx

Prefect length for C-85 lower center valve rocker cover when the standard 3/8 length has stripped..

a screw is a screw....

Perfect fit and great finish coating. Pricing was very reasonable.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping