Overview

|

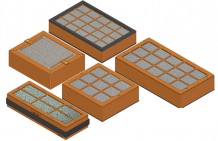

CENTER IT is a tool for drilling pipe and other round objects. CENTER IT is made specifically for use in a drill press. The V-block bolts to the drill press table and enables the drilling of round pieces parallel and centered. The grooves on the outer sides eliminate slippage while holding pipes, etc., for sawing on job sites or other applications. To use, simply place CENTER IT on the drill press table, run the bit down (with motor off) to hold the jig centered on the bit, then bolt the jig to press table. No clamping of the tube is necessary since the angled flats of the jig hold it centered. Holes will automatically be centered on the tube with no center-punching required. If tubing is too large to drill in a single operation it can simply be turned over.

Especially for the woodworking hobbyist, the metalworking enthusiast, and even the professional automotive mechanic, CENTER IT makes speedy and precise work of drilling tasks. Its "hand vise" grip ridges allow no-clamp holding of round stock for sawing and cutting. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

- CENTER IT is made of heavy aluminum extrusion.

- The dimensions are 5" Length, 4" Width, 1-3/4" Height

- US Patent No. 6435497

Reviews

Exactly what I needed . Works very well for what it is intended to do. Lightweight, well constructed and accurate.

Center It Hole Drilling Jig

This is a very good jig for drilling into round stock. The bottom groove is used to help centre the jig prior to drilling to ensure holes are perfect everytime. Also use this jig for supporting round stock on the bench for general purpose assembly. It is quite sturdy and well made.

Center It Hole Drilling Jig

For a short extrusion with four holes, this is a bit pricey. However, I had so many repeat holes to make, it earned its keep on the first job. Setup is fiddly in that everything can shift until all is tight, but if repeated accuracy is what youre after, you can achieve it with this little jig.

Center It Hole Drilling Jig

I havent used this yet but appears to be a well built V-block. Ive had another model in the past. This one appears to be a better built unit as it has more mass and a solid feel. I would recommend this V-block.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping