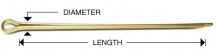

ACS Piston Pin Removal Tool

MFR Model# PT171

Overview

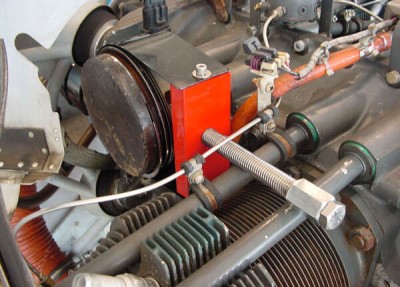

| This tool takes all the work and risk out of removing the piston pin. It works on most Lycoming and Continental engines. Just slip it over the piston, turn the shaft and it pushes the pin out smoothly and cleanly. Vinyl coated tip prevents scratching and marring the pin or piston during removal. Will handle up to 5.5" pistons. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

- 2 lbs (1Kg) shipping weight.

Reviews

Great tool, safe and easy removal of Piston Pin. *****

PT171 Piston Pin Removal Tool

PT171 Piston Pin Removal Tool

NICE ITEM - WORKED WELL - FAST SHIPPING. THANKS

PT171 Piston Pin Removal Tool

Works well

PT171 Piston Pin Removal Tool

Makes it easy tip remove piston pins

PT171 Piston Pin Removal Tool

This pin remover will not remove the piston pin from the number 4 cylinder on a cont. 0 470 engine cant get the clearence need to push the pin.

PT171 Piston Pin Removal Tool

This tool worked as well as expected in removing piston pins from an O-320. The big advantage is there is no side load put on the connecting rod.

Just tried it on a O320 and it worked great.

Good tool, like many good tools, required a slight modification to make it better. Used to remove E-225 5 Piston from right rear cylinder while still on aircraft. Tool wouldnt quite fit as delivered, as it was up against the adjacent cylinder barrel. Drilled additional holes further down the band and was able to get it into position and had the pin out within minutes.

O-360 A1D narrow deck, used for removing piston pin from #3, very difficult with #1 cylinder installed. Plastic cap on end of bolt separated from the bolt on 1st attempt. Managed to get it started but it stopped due to the large hole on the band not lining up properly over the piston hole. Take it all apart and have to modify the band holes on wooden block end to allow band to move around some. Had to use a nylon dowel plus the tool to get in all the way out. It worked, but space is a concern and I had to improvise. Quality is OK. All the above is why I rated it average.

PT171 Piston Pin Removal Tool

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping