- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

|

This chromium-nickel-molybdenum alloy, “king” of the hardening grades of alloy steels, possesses much deeper hardenability than the 4100 series. The fatigue-tensile ratio makes it ideal for highly stressed parts such as landing gear legs, and is often referred to as “spring steel”. Tensile strength is about 110,000 PSI. It is difficult to weld but can be welded by any of the common welding processes providing the section is preheated and stress relieved after welding. If Mfg. Test Reports are required, there's a minimum $15.00 charge per order. Please indicate P/N 01-01133 in the Special Instructions Box during the checkout process. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

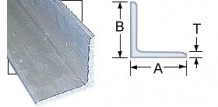

The listing was thickness x width. We have updated the chart to seperate these columns to be more clear. This material is priced and sold by the foot.