SAME DAY SHIPPING ON ORDERS PLACED BY 4 PM | 877-4-SPRUCE

Awi-Ami Stack Assy- C-300/400 Inconel

Select Version:

Left Hand

Left Hand Right Hand

Right HandOverview

|

Aerospace Welding Minneapolis, Inc. has earned a reputation for its uncompromising commitment to quality exhaust systems and components. We are an authorized distributor of AWI products,and as such can assure our customers of minimal down time and fast shipment through the Priority Service Program at AWI. All exhaust systems are built in fixtures for precise fit and are FAA approved for the listed aircraft. Available in factory new (N) and overhauled (OH) condition as noted. This Left/Right Hand Exhaust Stack Assembly is designed, engineered and manufactured using high quality components made from aerospace grade 601 inconel which provides reliable service and resist corrosion in high temperature exhaust system conditions. Visual inspection every 50 hours or 30 days. Remove tailpipes and inspect for cracks every 12 months. Inspect and pressure test exhaust system every 12 months. Replace Mult-Segment V-band clamps every 500 hours Remove the exhaust system from slip joints aft to turbo charger components every 2,500 hours or 12 months which ever occurs first. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

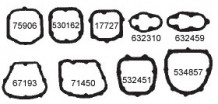

- Fits Cessna Models: 310P, Q S/N 310P0001 & ON

- 310R S/N R0001 - R2140

- T310R S/N ALL

- 340, 340A S/N340-0001 & ON

- 401 S/N401 - 0001 THRU 401-0322

- 401A S/N401A-0001 THRU 401A-0132

- 401B S/N401B-0001 THRU 401B-0221

- 402 S/N402-0001 THRU 402-0322

- 402A S/N402A-0001 THRU 402A-0129

- 402B S/N402B-0001 & ON

- 402C S/N C0001 & ON

- 404 S/N 0001 & ON

- 414 S/N 414-0251 THRU 4140965

- 414A S/N414A0001 & ON

Specifications

- Materials: 601 Inconel

- Part Condition: AWI FAA Approved New PMA

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping