SAME DAY SHIPPING ON ORDERS PLACED BY 4 PM | 877-4-SPRUCE

Sensenich Composite Pusher PropellerRotax 912 912S & 914

From $1760.00 to $2335.00

Overview

|

Improve your Aircraft’s performance with the 2 or 3 blade Rotax propeller featuring the new PowerSweep blade planform. This propeller is manufactured using an internal pressure, closed mold system to produce a hollow, one piece blade. This process yields very repeatable blades with maximum strength, durability, and low weight. Don't confuse this propeller with other propellers that are manufactured as two pieces and then bonded together afterwards. This propeller has the strength and durability to give you thousands of hours of trouble free flying.

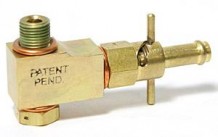

This propeller features a co-cured bonded stainless steel leading edge for erosion and FOD protection. The two piece hub is manufactured from aerospace grade aluminum and is either alodined or anodized for corrosion protection. The Pitch Cylinder Hub System allows its users to set a broad range of pitches, using the system’s index mark as a reference point when making adjustments. They adjust 16 degrees in pitch, affording maximum performance within an efficient aerodynamic envelope. The blade pins lock into the blade pin slot of the pitch cartridge, allowing the blades to move back and forth in tandem for ease of setting pitch. The 2 or 3 Blade Rotax propeller is suitable for use on the 912 80HP, 912S 100HP and 914 115HP. There are 2 blade lengths available, 75" and 70" diameters. Either blade can be trimmed to make propellers from 66" to 75" diameter. Composite spinners available for these propellers in 8", 9", 9.5" 10" 11" and 12" diameters |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- Internal pressure molded

- Carbon Fiber construction

- 2 or 3 Blade Tractor

- Easy Pitch Hub System

- Co-cured Stainless Leading Edge

- 66" - 75" Diameter

Specifications

- Material: Carbon Fiber

- Engine Suitability: Rotax 912 / Rotax 912S / Rotax 914

- Engine Type: Reduction Units Only

- Horsepower: 80 - 115 HP

- Available Rotation: Right Hand Only

Application

- Rotax 912, 912S, 914

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.