THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-4-SPRUCE

Joystick Articulation 3.9mm Videoscope - 1.5m Length

$10022.00/Each

Part# 12-06449

MFR Model# USA750J-4-1500

MFR Model# USA750J-4-1500

Overview

|

This advanced joystick articulating videoscope offers a 3.9mm probe with dual camera imaging. No more lost or cross threaded side view tips! Just push a button and switch to front or side view. HD image quality borescope with probe lengths available in 1.5- and 3.0-meter lengths. The large 5-inch touch screen is IP54 water and dust resistant. The rugged and durable borescope system is securely packaged in a custom designed heavy-duty case.

Designed for applications where high mobility is needed, the USA750 is lightweight, rugged, and provides high-resolution images and advanced imaging functions that allow workers to fulfill their tasks in even the most challenging environments. The USA750’s software includes a file management system that allows you to sort photos and videos into session folders. You can write notes or annotations and add them to your images. A compare function enables you to compare the live view image to gallery images. You can also include logos and watermarks as well as session tags. These functions make keeping track of all your inspections easy and convenient. Tungsten Rigidity All USA750 insertion probes are tungsten braided and are waterproof up to 1m depth for 30 minutes. The natural abilities of the tungsten metal give our insertion probes increased heat (up to 100° C / 212 F). The strength and density of tungsten extend the probe lifespan significantly, protecting them from scratching or abrasion. Shorter Distal End & Bending Radius The bending angle is crucial to ensure maneuverability within the object and to enhance the field of view. Therefore, our insertion probes offer a shortened distal end and a bending angle of up to 140°. Videoscopes allow users to see inside the inspection area without having to disassemble or destroy them so users can identify problems early on and repair parts before they fail or cause critical damage. That is the main reason why borescope cameras fall into the category of Non Destructive Test Equipment. The USA 750 borescope system keeps the advantages of USA200 and 360 articulation’s user interface but embraced the modular design that some professionals desire. Tungsten braid tube and bending neck are introduced on the 6.0mm probe which brings the high rigidity performance to compete to all hi-end competitors. 4mm shorter distal end than the previous generation provide smaller bending radius and at the same time, improved lock system mechanics gives the same smooth articulation control tension feel compare to the popular electronic control system in the market. The dual camera tip on this mini borescope changes everything. No more cross threaded or lost side viewing tips. Just push a button and toggle between a front view or side view on the large 5-inch color screen. Gone are the days of getting the probe tip exactly where you want it only to find out that you need to change tips. Simply push a button on the borescope control station and change views. With either view you can modify the LED light output and capture videos or still images. Benefits of Using Videoscopes for Maintenance and Quality Inspections: HD recording: Videoscopes allow users to record high-definition images of the inspections which allows for detailed inspection and analysis. Our Videoscopes with articulating insertion probes can reach confined and hard-to-reach areas, making what seemed impossible to be the standard. The ability of the video borescope to detect issues early on helps to avoid costly downtime and ensured that equipment is operating smoothly. Our Videoscopes are water and chemical resistant, making them ideal for inspecting in wet and harsh environments. Our Videoscopes are easy to use, even for untrained personnel. This makes them a valuable tool for maintenance, quality inspections and troubleshooting. Its advanced imaging capabilities, ability to access difficult areas and efficient inspection time make it the perfect tool for ensuring quality and performance of your specific inspection application. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- USA750J Main System:

- Lightweight and ergonomic

- One-handed operation

- 5" LCD touchscreen

- IP54 protection

- HDMI / USB Type-C / Wi-Fi connectivity for Mobile App

- Backside camera

- File management, annotation, and comment functions

Specifications

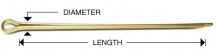

- Diameter: 3.9mm

- Length: 1.5 meters (4.9ft)

- Camera Tip Length: 21.6mm

- Direction of View: Front View / 90° Side view

- Illumination: Front / Side LEDs

- Field of View (FOV): 120°

- Depth of Field (DOF): 5mm ~ 100mm

- Still Image Resolution(.jpg): 1600*1600

- Video Resolution (.mov): 1600*1600

- Articulation Angle: 360° Rotation / 120° Angle

- Camera Housing Material: Stainless Steel

- Probe Sheathing: Tungsten Braid

Documents

- Instruction Manual (PDF)

- Data Sheet (PDF)

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping