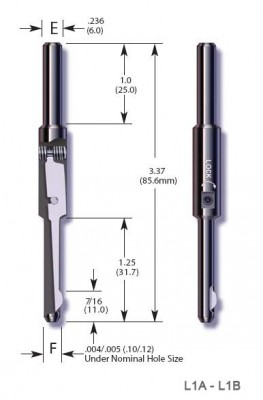

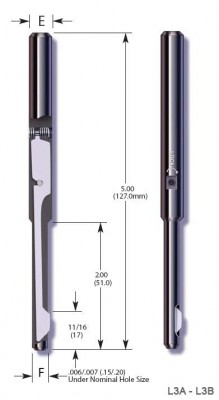

| HOLE DIAMETER | SHANK DIAMETER | BLADE SERIES | Part No. | Price | Buy |

|---|---|---|---|---|---|

| 3/32 in. / 2.38mm | .236 in. / 6.00mm | L1A | 12-02949 | $115.75 | |

| 1/8 in. / 3.17mm | .236 in. / 6.00mm | L1B | 12-02951 | $110.75 | |

| 5/32 in. / 3.96mm | .250 in. / 6.35mm | L2A | 12-02952 | $99.75 | |

| 3/16 in. / 4.76mm | .250 in. / 6.35mm | L2B | 12-02953 | $102.75 | |

| 1/4 in. / 6.35mm | .359 in. / 9.10mm | L3A | 12-02955 | $102.75 | |

| 2.50mm | 6.00mm | L1A | 12-02959 | $108.90 | |

| 3.00mm | 6.00mm | L1A | 12-02960 | $108.75 | |

| 4.00mm | 6.00mm | L2A | 12-02961 | $100.75 |

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

|

E-Z Burr High Speed Steel (HSS) tools are the industry standard for quick, effective and consistent front and rear burr removal. No other HSS deburring tool is this durable. By designing the blade to operate independent from springs and plungers, E-Z Burr has created a deburring tool with a flexible blade and a solid shank for optimum performance for deburring metal or plastic components. In addition, the patented E-Z Burr HSS deburring tool allows you to change chamfer settings, from extreme low to extreme high, and cutting blades without removing it from the holder. Once the desired chamfer is set, it won't change, even from blade to blade. The result is less downtime, more production, and higher profits.

HSS is known for its quality performance at low surface speeds to provide a good surface finish. It can withstand higher temperatures without compromising its hardness, which allows HSS to cut faster than high carbon steel. HSS also typically offers a high abrasion resistance when compared to carbon and other generic tool steels. The inherent toughness of HSS makes it an economical choice for doing batch runs or in a production environment when a reliable, stable performance is required. It is also the best choice when limited spindle RPM or horsepower is available. Unlike carbide, HSS can cut at slower speed and feed rates and therefore it is a great choice for deburring holes when using hand tools. E-Z Burr Tool Specifications: Series L1A and L1B tools have a working range of -0.0 + .006 inches and -.03 + .15mm. Series L2A and L2B tools have a working range of -0.0 + .016 inches and -.10 + .40mm. Series L3A and L3B tools have a working range of -0.004 + .015 inches and -.10 + .40mm. Note: All tools (front and rear cutting blade with positive rake) |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Works as advertised. Great solution to an unusual task, deburring the back side of blind rivet holes.

EZ Burr High Speed Steel 1/8

Must-have for rivet work, but the 1/8 tool is fragile. If you get into a crooked hole, e.g. a drilled-out rivet hole that is out of round, without knowing it, the blade will catch and break. Blades are replaceable. Sometimes the chamfering blade will catch and twist the entire shank, ruining the tool. Be gentle with the 1/8 tool. Have not had any problems with the 3/16 and 1/4 tools. Replacement blades are available elsewhere. Aircriaft Spruce, would you please look into carrying the replacement blades for these? That would be much appreciated.

Great tool and time saver , get it dialed in and go to town, cuts debur time in 1/2

This tool saves so much time, its worth twice the price. If I could give it 6 stars I would.

Great tool, works as described. Will save a lot of time.

Mixed results with this tool, it’s great for impossible to reach back of hole locations, but it either chamfers too much, unequally from my experience front and back of hole or won’t remove the burr. I have played with the settings for hours with the same result. I wouldn’t recommend the $80+ spent for this tool. But as with everything, YMMV. Good luck and ACS rocks!

EZ Burr High Speed Steel 3/32

Tried it. Does not come with instructions. I gave up using it because Im unable to get it set correctly. Your results maybe be more favorable. I dont plan to use it ever again.

EZ Burr High Speed Steel 1/8

I tried using them on aluminum sheets and unfortunately, this tool significantly enlarges the diameter of the hole as it passes through. Unusable for my needs.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Our part number 12-02951 is manufacturer number ezl0125, and it comes with one blade insert.