ATS Voyager Articulating Video Borescope

Add to cart for current price

MFR Model# ATS-VS22

Overview

|

Videoscopes have all but replaced traditional fiberscopes for endoscopic inspections -- and with good reason. They have much higher resolutions; they have no fibers to break; they cost less to manufacture; they can be made to any length; and most importantly they can record real-time video and still images of the inspection area. That's the key to a videoscope: you can record your inspections on SD cards and store them with your maintenance logs. It's an excellent way document maintenance issues, train mechanics, monitor progressive conditions, provide evidence of work, etc. The state-of-the-art ATS Voyager videoscope features an articulating tip that swings 240 degrees to reach every inspection point of an airplane. With a simple turn of the control knob, you can move its Tungsten-sheathed tip from side to side to look left, right, and even backwards! The ATS Voyager gives you unprecedented access to areas that simply cannot be reached with a straight probe. Included with the ATS Voyager is a 70 degree tip mirror to look at right angles to the normal line of sight. And on that score, the ATS Voyager features a remarkable innovation that places an extra set of LED lights to the side of the probe, which when activated, successfully eliminates the glare and spots that are sometimes present when looking through a mirror. The result is an absolutely crystal clear, well lit, image through the tip mirror. It's a brilliant idea that you'll be seeing on other videoscopes in the future. The camera captures video and stills at a resolution of 640x480 pixels, and optionally stores them to an SD card. The 3.5" display shows images with excellent clarity. The flexible 1 meter probe bends to any shape, while the sealed 6mm tip will resist dirt, scratches, and abrasions associated with normal use. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- 2-Way Articulation 120° side to side (240° total)

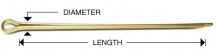

- 6.0mm diameter probe

- 1 meter long probe (other lengths available)

- 70° Field of View (FOV)

- Focal Range: 15mm to infinity

- Direction of view: 0° (70° with included mirror)

- Illumination from 4 forward LEDs (and 2 selectable right angle LEDs)

- Display 3.5" LCD

- Picture resolution: 640x480

- Video resolution: 320x240

- Records to SD card

- Mini USB and A/V out interfaces

Documents

Videos

Reviews

This works great!! exactly what we needed to complete this job. Weve already found numerous different types of jobs that this will help immensely on. Great versatile product!

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Made in Taiwan.

FREE Shipping

FREE Shipping