THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-4-SPRUCE

Winter 2-1/4 Variometer 8061 Ebv 1000 Foot Min Log

$680.00/Each

Part# 10-05644

MFR Model# 8061

MFR Model# 8061

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

|

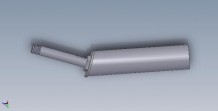

Vane type variometers measure the change in air pressure inherent to changes in altitude. The instrument consists of a cylindrical chamber with a precision-fit baffle plate (vane) rotating on shock proof jewel bearings and centered by a coil spring. The vane divides the chamber in two: one section is open to static pressure, while the other is connected to an expansion tank, in which a volume of air is insulated against the thermal effects. Differences in pressure are compensated by the narrow gap between vane and chamber wall. There is a change in static pressure when an aircraft climbs or descends, and a differential pressure is established between the two sections of the chamber. The resultant deflection of the vane provides a measure of the vertical speed and this deflection is transferred to the pointer of the instrument. The response rate of a variometer is important. In high-performance gliding, up currents

can be identified all the quicker and used all the more efficiently if the variometer responds without delay. Defined as the length of time the instrument takes to reach 65% of its final reading in response to a sudden change in vertical speed, the time constant serves as a standard for gauging speed of

response. The faster a variometer responds, the smaller is its time constant.

Vane type variometers with large measuring ranges such as 5 StV 5 (±10 m/sec. and ±15 m/sec.) have small time constants. The volume of the expansion tank must be increased in order to achieve comparable figures with variometers having the most common measuring range (±5 metres/second).

The tiny housings mean that these instruments can be installed even where space is restricted. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping