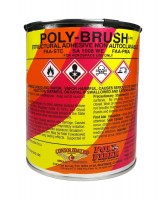

Alcohol Resistant Gas Tank Sealer Gallon

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

Overview

|

This is impervious to all fuel types. Over 2,000,000 sold to date. It is the best way to repair and restore your fuel tank. Simple application, includes extensive application information and product information sheet. Will seal pinhole leaks and prevent rusting. 1 Pint will seal a 10-12 gallon tank. Good for all fuel types. Works well with all metal and fiberglass tanks. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Very good product

Alcohol Resistant Gas Tank Sealer Gallon

I used this product 10 years ago in a heavily rusted MGB tank with pin holes. I dropped about 10 ft of chain in the tank and vigorously shook it until all he rust flakes were loose cleaned out and added sealer as directed. To this day still no leaks.

Used it as a sealer in my motorcycle gas tank. Hasn’t leaked yet. Easy to use and cures easily. Recommended big time!

This product is the real McCoy. It was amazing, as it coated the entire inside of the tank. I was rolling it around (as directed) the white was seeping out of seams that I didnt even know had leaks. It sets up quickly, and I was putting fuel in the tank after 3 days. I would highly recommend this product

Very easy to use. Smooth tough film when dry. Dried thoroughly in 24 hours. Lower areas of tank seem to have a thicker film coverage than vertical and top surfaces.

I used the product in a fiberglass fuel tank it seems to dry and produce a nice film. I would definitely purchase more than necessary to be able to slosh it around and have another person to assist you. I purchased a gallon for a 36.5 gallon tank and had a lot left over. The product is reasonably price and can be used again if stored properly. I haven’t put fuel in yet but very confident it will be fine.

No instructions with product, or on can and little information on internet.

Alcohol Resistant Gas Tank Sealer Gallon

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Per the vendor, if it is used shortly after purchase, part number 09-03477 should not need anything to thin out the product. Make sure it is well mixed and it should be fine without any additional products.

This sealer is only recommended for metal or fiberglass fuel tanks.

This is a tricky question. Yes it should work, but there are no specific tests done with any specific epoxy or resin system used to make a fiberglass tank. As long as the tank is cleaned and prepped properly, it should work just fine.

This is a tricky question. Yes it should work, but there are no specific tests done with any specific epoxy or resin system used to make a fiberglass tank. As long as the tank is cleaned and prepped properly, it should work just fine.

Per out product support manager: it is a sloshing material that will fill small pin hole leaks and seal the inner tank. It can be poured in and sloshed around in a fuel tank.

Per the supplier: this product has a 2 year shelf life that starts once it is opened.

Per the manufacturer: The entire interior of the tank must be dry. If only one small area of the tank is not dry or has foreign matter that may keep the sealer from adhering, the sealer will not stick to those areas and could come loose and float around in your tank and eventually come through the fuel pick up tube and clog the fuel pump and carburetor. The solvent for this sealer is methyl ethyl ketone (mek). Before introducing any additives to fuel tank after sealer has been installed, be sure that the product you introduce does not contain (mek). (mek) can soften and loosen the sealer which in turn can clog your fuel lines, carburetor, etc. Avoid using "gumout" or similar products which have been known to use (mek).

The 09-03477 is a sloshing sealer that gets poured in a fuel tank and the tank rotated so the material gets on all parts of the tank. The 09-38560 is a much thicker material and requires a brush to spread the material.

The primary purpose of this material is to coat the inside walls of a fuel tank for protection. It is a pour in and slosh around material. I could not find any information as to how well it would work if brushed on, or what size pin holes, or rivets, it would seal.

This is a single stage component. There is no thickness that we recommend. Each application can vary. The product generally leaves behind a very thin coating. It is not supposed to be very thick. The idea is to pour the product in to the tank and slosh it around. Once all of the walls of the tank have been hit, they customer should drain the remaining sealer out back in to the can. There should be no puddling of the product as this will prevent it from drying properly. If the customer wants to do a 2nd coat after 24 hours with the remaining product, that is fine. This is only needed if for some reason they missed a spot during the initial application. A thicker coat or 2nd coat really won't offer any added benefit in terms of protection.

FREE Shipping

FREE Shipping