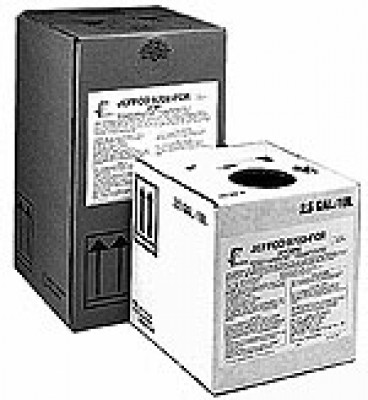

Jeffco 3102 Standard Hardener 40 Lb

MFR Model# 614979

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

| Type | Description | Part Number |

|---|---|---|

| Fast Hardener | 3102, Pail (40 lbs) | 01-07920 |

Overview

|

1307 Low Viscosity Resin / H-3102 Fast Epoxy Hardener - 100% solids two component epoxy laminating system with excellent wet out, low viscosity and high strength. Very low odor and toxicity. Easy to use, Mix Ratio: 4:1 by volume; 100:22 by weight. Gel Time: 12-15 minutes @ 77°F (150 grams). Fast curing products for a variety of use applications. Used for fast curing, penetrating wood coatings, adhesives and sealers, fiberglass laminating and microsphere filled fairing compounds. Excellent cold temperature cures down to 40 degrees F. No solvents or VOCs. Non-hazardous, non-corrosive hardener. H-3176 30-minute Medium R/T Epoxy Hardener- Safety Press Molding Epoxy Hardner. Good low temperature cure. Fast wetting of fiberglass reinforcements. Easy to use 4:1 mix ratio by volume; 100:22 by weight. Gel time: 25-30 minutes @ 77°F (150 grams). High HDT at room temp, increasing with post cure. Low toxicity, very low odor. Non-hazmat. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

use fast hardener, it works great and you get enough time for job(s). This resin mix has the advantage to be ok for sanding only one day after, still in curing process but easy to sand without clogging sanding paper or device. It was not the case years ago. To Brian J. comment : all adhesives and epoxies get out of control today :( To Claude P. comment : yes its true, years later same issue but its not last dispatching shipment trouble, I got well outside cardboad box but inside it, all 1Gal Rhino damaged, so this occurs before last packaging.

It works well for potting our product.

great stuff

The delivery to Malmö Sweden was very fast , ( 2 days!)thank you Aircraft Spruce and U. P. S. , than came the cov. 19 slow motion at the customs !!

Like using it

Very happy with this product

Nothing wrong with the product itself however, this is the second time in a row that I receive this kit with damage to the containers that occurs during shipping. I have informed customer service about shipping damage and it is still happening. I wish the packing department would consider how irresponsible shipping companies are with packages.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Yes, we have added the Tech Data Sheets to this web page under the "Documents" tab.

Per the supplier: As long as the lid stays on it and it is nice and tight, it should last about 1 year.

This has 5 one gallon cans of resin and 1 gallon can & one quart can of hardener. When mixed, it should yield approx. 6.25 gallons of laminating material.

FREE Shipping

FREE Shipping