FREE SHIPPING ON ORDERS OVER $350 (SOME EXCLUSIONS APPLY) | 877-4-SPRUCE

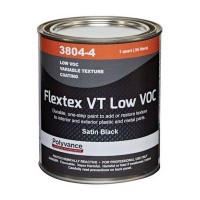

Low Voc Flextex Vt Reducer - Quart

$50.65/Each

Part# 01-01639

MFR Model# 3804R-4

MFR Model# 3804R-4

Overview

| Flextex VT Low VOC is a tough, variable texture material formulated to simulate textured automotive plastics and metal. It can be used over or under most finishes and may be top-coated with Bumper and Cladding Coat paint, base/clear or single stage paint systems. Flextex VT Low VOC has excellent durability and may be used as the finish coat where black texture is needed. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- For best results, apply Flextex VT Low VOC over a primer surfacer sanded with 320 grit. See www.polyvance.com for info sheets and instructional videos on texturing.

- To build texture, apply 3 to 5 light “splatter” coats allowing flash time between coats. Move the gun quickly and don’t flow out the paint. Reduce fluid flow at the gun for light coats. Let dry 30 minutes if light coats are applied and 2 to 3 hours for heavier applications before top coating. For more details on applying Flextex VT, see reverse side for application S.O.P.

- Flextex VT may be top-coated with a lacquer compatible top coat system.

- Clean spray gun immediately after use with lacquer thinner

Texturing Reference

- Use a test panel for determining the textured desired. Painting with limited amounts of reducer and low air pressure at the gun will produce the coarsest texture. For finer textures, reduce the paint with 3804R-4 Flextex VT Low VOC Reducer up to 200%.

- Heavy Texture: Spray Flextex VT mixed 8:1 (paint: reducer) using a 1.8 mm spray gun at 25 psi.

- Medium Texture: Spray Flextex VT mixed 3:1 (paint: reducer) using a 1.8 mm spray gun at 25 psi.

- Fine Texture: Spray Flextex VT mixed 1:1 (paint:reducer) using a 1.8 mm spray gun at 25 psi.

Benefits

- Simulates OEM textures

- Only one texture paint needed for all texture sizes

- Compatible with nearly all topcoat systems

- Does not require topcoating if black texture is desired

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping