(Hover to zoom | Use mouse wheel for +/-)

Overview

|

Installation hole size for the A-T Series Insert is determined by the parent material's thickness and density. The thicker the material the larger the hole required to allow full 360° installation swaging. The application should be tested before hole size is specified. The A-T Series Insert is unique in that it can be installed into most any material above .030/,76 mm in thickness. As the A-T Series is installed, the threaded portion is completely swaged 360° into the sleeve portion and the hole. This permits the A-T Series to be used with Grade 8/metric 12.9 mating screws. The A-T Series Insert is installed using lightweight, hand held pneumatic tools that can be located at any position in your product's assembly sequence. The A-T Series Insert can be installed either prior to or after finish. 360°SWAGING HOW IT WORKS FOR YOU As the A-T Series Insert is installed, the threaded nut portion is drawn into the upper sleeve portion.As this occurs, a 360° swaging action takes place anchoring the A-T Series in the parent material. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reference Chart

| Thread Size | .030-.090 Mat. Thickness | .091-.124 Mat. Thickness | .125-.186 Mat. Thickness | .187-Over Mat. Thickness | ||||

| Drill Size | Decimal | Drill Size | Decimal | Drill Size | Decimal | Drill Size | Decimal | |

| 4-40 UNC | 3/16 | .1875 | #10 | .1935 | #10 | .1935 | #9 | .1960 |

| 6-32 UNC | 7/32 | .2188 | #2 | .2210 | #1 | .2280 | #1 | .2280 |

| 8-32 UNC | 1/4 | .2500 | "F" | .2570 | 17/64 | .2656 | 17/64 | .2656 |

| 10-24 UNC | 9/32 | .2812 | "L" | .2900 | "L" | .2900 | 19/64 | .2969 |

| 10-32 UNF | 9/32 | .2812 | "L" | .2900 | "L" | .2900 | 19/64 | .2969 |

| 1/4-20 UNC | 3/8 | .3750 | 3/8 | .3750 | "W" | .3860 | 25/64 | .3906 |

| 1/4-28 UNC | 3/8 | .3750 | 3/8 | .3750 | "W" | .3860 | 25/64 | .3906 |

| 5/16-18 UNC | 1/2 | .5000 | 1/2 | .5000 | 33/64 | .5156 | 33/64 | .5156 |

| 5/16-24 UNC | 1/2 | .5000 | 1/2 | .5000 | 33/64 | .5156 | 33/64 | .5156 |

| 3/8-16 UNC | 9/16 | .5625 | 9/16 | .5625 | 37/64 | .5781 | 37/64 | .5781 |

| 1/2-13 UNC | 3/4 | .7500 | 49/64 | .7656 | 25/32 | .7810 | 51/64 | .7970 |

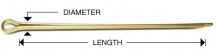

| Thread Size | Thread Call Out | HD ±.005 | L ±.015 | D Max. | IL Max. | LB ±.015 | ILB Max. | IATD** Max. | Hole Depth Min. | Part No. |

| 4-40 UNC | 440 | .211 | .370 | .1875 | .205 | .660 | .495 | .395 | .400 | ATS2-440 |

| 6-32 UNC | 632 | .240 | .370 | .2185 | .205 | .675 | .505 | .410 | .400 | ATS2-632 |

| 8-32 UNC | 832 | .269 | .370 | .2495 | .205 | .675 | .505 | .410 | .400 | ATS2-832 |

| 10-24 UNC | 1024 | .306 | .370 | .2805 | .205 | .685 | .520 | .385 | .400 | ATS2-1024 |

| 10-32 UNF | 1032 | .306 | .370 | .2805 | .205 | .685 | .520 | .385 | .400 | ATS2-1032 |

| 1/4-20 UNC | 420 | .400 | .515 | .3745 | .275 | 1.005 | .760 | .615 | .540 | ATS2-420 |

| 1/4-28 UNC | 420 | .400 | .515 | .3745 | .275 | 1.005 | .760 | .615 | .540 | ATS2-428 |

| 5/16-18 UNC | 518 | .528 | .615 | .4995 | .325 | 1.065 | .770 | .630 | .640 | ATS2-518 |

| 5/16-24 UNC | 518 | .528 | .615 | .4995 | .325 | 1.065 | .770 | .630 | .640 | ATS2-524 |

| 3/8-16 UNC | 616 | .588 | .745 | .5615 | .390 | 1.450 | 1.095 | .890 | .770 | ATS2-616 |

| 1/2-13 UNC | 813 | .800 | .935 | .7485 | .485 | NA | NA | NA | .960 | ATS2-813 |

Documents

Reviews

Quik shipping and great product

Nutsert 1/4-20 AtS2-420

Nutsert 10-32 AtS2-1032

Nutsert 1/4-28 AtS2-428

Good product

Nutsert 8-32 AtS2-832

Good forget ge right application. Steel alloy inverts will take more torque and designed to grip the OD recess better. But the OD diameter is larger and the incert is deeper. These aluminum nutcerts are great for what they do. The manufacturer offers great support as well. Terrific people. Good investment.

Nutsert 6-32 AtS9T-632

one of the best ways to get an attachment point

Nutsert 8-32 AtS2-832

one of the best ways to get an attachment point

Nutsert 6-32 AtS9T-632

I really like these inserts, and really like how fast you ship them out! Thank you!

Nutsert 8-32 AtS2-832

great service,thanks.

Nutsert 5/16-18 AtS2-518

Nutsert 5/16-18 AtS2-518

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

They are both quality blind nuts, but we do not have any data that compares the two. Nutserts are the more popular units, and that may be because of the shorter lip in the surface of the hole, and nurreled outer surface to help prevent the unit from spinning once installed.

Nutserts can be installed with AA-112 Hi torque tools, AAT916 expandable tools, or a AAT312A master nutsert kit. See Accessories.

All of the nutserts listed on this page are made of carbon steel.

These two nutserts will have lengths on approximately .375"

For size ATS2-440, it is 9 in/lbs.