SAME DAY SHIPPING ON ORDERS PLACED BY 4 PM | 877-4-SPRUCE

Superior Millennium SL36000N-A20P Cylinder Complete Assembly

$1395.00/Each

Part# 07-17947

MFR Model# SL36000N-A20P

MFR Model# SL36000N-A20P

Overview

|

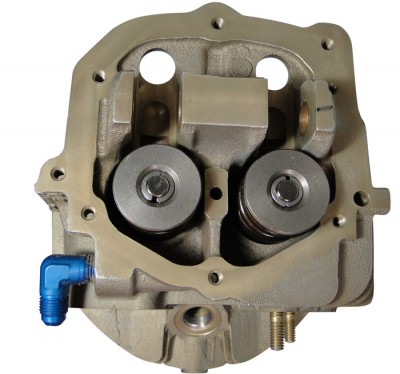

Complete New Millennium Cylinder Assemblies contain the following new parts: head, barrel, valves, valve seats, valve guides, piston, rings, gasket kit, seals, springs, rotocoils, and rocker shafts. The cylinders will not include piston pins or rocker arms. #1 Aftermarket Cylinder in the World! With well over 100,000 currently in service around the world and millions of flight hours behind them, Superior’s Millennium Cylinders® are without question, the most popular FAA-approved, PMA aftermarket cylinders in all of general aviation. But Superior is not just the world’s #1 dedicated cylinder supplier we are also the leader in cylinder design and performance innovation. Each Millennium Cylinder is an engineering and manufacturing masterpiece. From its advanced computer generated head fin configuration, to its 3-D port contour and increased wall thickness, to its advanced aluminum alloy heads and through hardened AMS 6382 steel barrel, Millennium Cylinder’s deliver performance and quality benefits far surpassing anything else in the air. Looks great. Performs better. Put any Millennium Cylinder side-by-side with any other OEM or aftermarket cylinder and the difference in quality, craftsmanship and attention to detail is strikingly obvious. And while it looks really great, it performs even better. Millennium Cylinders resist cracking, run cooler, last longer and generally out perform the standard cylinders available from Lycoming, Continental or any other aftermarket supplier. We’re so confident in the Millennium Cylinder’s performance that it’s covered by a full 25-month/TBO* (whichever comes first) warranty. It’s one of the best in the business. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features / Benefits

Advanced Aluminum Alloy HeadsMillennium cylinders are manufactured from the most advanced alloys available. That means their structural strength exceeds the latest aerospace industry requirements for air-cooled cylinder heads. In addition, our head castings meet, or exceed, the industry’s more stringent standards for porosity and shrinkage.

Increased Port Wall Thickness

The Millennium cylinder’s unique design also features increased port wall thickness to eliminate problems with premature warpage and cracking. In addition, the exhaust and intake ports are volumetrically matched to maximum output and performance.

Computer-generated Head Fin Configuration

Millennium cylinders feature new and advanced computer-generated head fin configuration that provides more consistent head fin thickness and spacing – that means they deliver more uniform heat transfer and fewer “hot” spots.

Improved Cooling

Millennium cylinders also have aerodynamically smoother surfaces to reduce wind resistance, which enables ambient air to more rapidly draw heat away. Bottom line: Millennium cylinders run cooler and cooler cylinders last longer.

Very high quality casting

Millennium cylinders perform better because they are made better. Our extremely high-quality castings create aerodynamically smoother surfaces to improve overall airflow and cooling.

Through hardened steel barrels

The barrel of each Millennium cylinder offers uniform hardness all the way through the steel walls allowing the barrel to provide even wear while withstanding extreme cylinder temperatures and pressures. This means Millennium cylinders typically reach and often exceed, recommended TBO times.

Ams6382 steel barrels

Millennium cylinders are manufactured with ams6382 steel barrels ensuring complete control of all critical manufacturing processes from the grain size of the steel to the elimination of both micro-impurities and defects in the alloy.

Advanced cylinder barrel choke

Our advanced manufacturing techniques also enable us to craft the Millennium cylinder’s barrel choke from 10 to 13 thousandths of an inch, allowing the rings and pistons to work more efficiently throughout the normal operating temperature range.

Volumetrically matched ports

The intake and exhaust ports on each Millennium cylinder are volumetrically matched for maximum output and performance.

Parts in Assembly

| Part | Quantity | Part Description |

|---|---|---|

| SL61681A | 1 | GUIDE, INT. VALVE |

| SL72057A | 1 | INSERT INTAKE VALVE SEAT |

| SL72058A | 1 | INSERT EXHAUST VALVE SEAT |

| SL74230A | 1 | GUIDE, EXHAUST VALVE |

| MS20823-8D | 1 | ELBOW |

| MS9018-05/2-52 | 2 | HELICOIL |

| SL-STD-1872 | 2 | INSERT, HELICOIL 1/8-27 NPT |

| MS49005-2 | 2 | PLUG |

| SL31C-12 | 2 | STUD, 5/16 IN DIA, COARSE THRD |

| SL25C-9 | 1 | STUD |

| SL66610 | 4 | BUSHING, ROCKER, SHAFT |

| SL32006N-A1 | 1 | CYLINDER STUD |

| MS13998-3 | 1 | CAP |

| MS13997-3 | 2 | KEY |

| SL10077 | 1 | SEAT, VALVE, SPRING |

| SL11795 | 2 | INNER VALVE SPRING |

| SL11800 | 2 | SPRING |

| SL13323 | 1 | SEAT, VALVE SPRING |

| SL16475 | 1 | SEAT, VALVE SPRING |

| SL19001A | 1 | VALVE, EXHAUST (ROTOR TYPE) |

| SL73938 | 1 | VALVE, INT. |

| SL60009 | 2 | KEY, VALVE |

| SL65441 | 1 | SPRING SEAT |

| SL12272 | 1 | LOCK PLATE |

| SL18661 | 2 | SEAL - SHROUD TUBE |

| SL70310 | 2 | O-RING |

| SL71481 | 1 | RING, OIL SEAL, 4.84 ID X .04 |

| SL71973 | 1 | GASKET |

| SL75906 | 1 | GASKET |

| SL13790A | 1 | SHAFT, ROCKER VALVE |

| SL12892 | 2 | THRUST BUTTON |

| SL14995 | 1 | SPRING |

| SL61247 | 1 | 235/360/540 VALVE COVER |

| SL74241A | 2 | RING, PISTON |

| SL73857A | 1 | RING, OIL CONTROL |

| SL75413A | 1 | PISTON |

Eligibility

Narrow Deck:*Note: For Wide deck see: P/N: 08-16432

Documents

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping