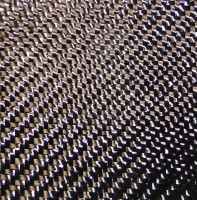

Bidirectional Woven Kevlar - Style 350

MFR Model# 350 CS800

- JUMP TO

- Overview

- Spec Chart

- Reviews

- Q&A

- View in Catalog

Overview

|

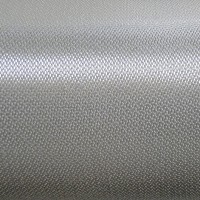

**Note: These products are sold by the yard** # 120 ( # 350 ). 1.8 oz per Sq/Yd. Thickness: .0035". Weave: Plain "Kevlar" 49 aramid fiber was introduced commercially in 1972 and is the Du Pont registered trademark for its new high strength, high modulus organic fiber. It combines high tensile strength (43,000 PSI) and high modulus (19 million PSI) with light weight and toughness superior to other reinforcing fibers for plastics. It is available in yarns and rovings which meet all FAA requirements for flammability. It shows no degradation in jet fuel, lubricating oils, water, salt water or high humidity. At cryogenic temperatures (-320°F.) performance is excellent with essentially no embrittlement or degradation of fiber properties. Kevlar 49 can offer both a significant weight saving and improved stiffness versus glass in addition to superior vibration damping and good impact resistance. A kayak made with Kevlar 49, for example, weighs about 18 pounds while the weight of a comparable boat made with glass would be over 30 pounds. The advantages over glass in small aircraft are similar - weight savings and improved impact resistance. Kevlar 49 is used in a number of parts on the Lockheed L-1011 because of weight savings of up to 30% compared to similar parts made of glass. One unusual benefit of Kevlar is its "quietness". A cowling made of Kevlar will be quieter and less sensitive to engine vibrations than its glass or graphite counterpart. Although all of the processes used in combining resins with glass fiber are adaptable to Kevlar 49 with little or no modification, it has been found that the vinyl ester type system is most compatible. The use of polyesters is not recommended because of poor bonding with Kevlar. The modified epoxy resin system featured in this catalog is compatible with Kevlar 49 and has good wetting characteristics. Kevlar 49 is stocked in three different fabric styles. Kevlar #120 is a very lightweight fabric, while #281 and #285 are identical except for the weaving pattern. Other weights and weaves of Kevlar are available on a special order basis. Be sure to specify the Kevlar style when ordering. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Spec Chart

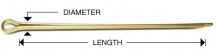

Oz./SqYd. | Lbs/Inch | ||||||

| 120 | |||||||

| 281 | |||||||

| 285 | |||||||

Reviews

Just what I needed, arrived safe and sound!

Kevlar - Style 350 1.8 38

delivered exactly as expected. Well packaged

Kevlar - Style 350 1.8 38

Perfect product for model airplane work.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Hexcel superseded the 120 style with the 350, but the material never changed, its the exact same.

You can use West Systems Epoxy on Kevlar fabric. We do not offer any uni-directional Kevlar cloth or Kevlar tapes. We only stock plain and twill weave Kevlar.

Kevlar is yellow in color, and will change in tone, but will continue to be yellow when epoxy is applied.

FREE Shipping

FREE Shipping