Oil Door Hinge Replacement Spring

MFR Model# 4640-1

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

|

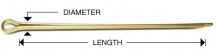

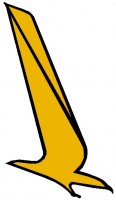

Replacement hinge for the Avery Oil Door Hinge. The hidden hinge has a uniquely shaped arm that allows the hinge to be mounted completely out of view to the underside of the cowling. The center hinge eye is removed for the custom made spring that loads the hinge to be full open when unlatched. If your oil door unlatched it will be full open, eliminating accidentally taking off with the oil door unlatched. The hinge is aircraft quality extruded MS20001-4 hinge with a 3/32” steel hinge pin. One end of the hinge pin is flattened. When installed and closed the hinge pin is gripped tightly by the force of the spring. Install the hinge so that the curved part of the hinge just misses the cowling when opening. We suggest you remove the spring to make it easier to see the range of motion during mounting. Mount the hinge to the cowling first; then mount the oil door to the hinge. Some builders may want to make an aluminum door instead of using a fiberglass door. Latching of the oil door can be accomplished with screws, camlock, dzus, hartwell latches, remote latches, etc. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Oil Door Hinge Replacement Spring 4640-1

Perfect match for the door on the Glassair (experimental II-RG)

Oil Door Hinge Replacement Spring 4640-1

never needed a backup...but good to have one.

Oil Door Hinge Replacement Spring 4640-1

Works great, drill the dimples out w a 3/32 tap the hinge pin out, u may have to reduce the length of a hinge section for this to fit in place. Once the coils fit. Side the pin back in place and stake the ends.

Oil Door Hinge Replacement Spring 4640-1

Oil Door Hinge Replacement Spring 4640-1

Good to have spare spring available for oil filler door.

Oil Door Hinge Replacement Spring 4640-1

Working on a customers cowl and didn’t even know the spring was there. Glad Aircraft Spruce has these, otherwise it would have been a bunch of searching.

Also a spring replacement for Cessna wheel pant access door.

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping